Never dealt with oily water treatment before? You are not alone, most of our customers will only select an oily water separator once in their career. Maybe you’ve seen it go wrong and want to make sure you don’t waste money on the wrong system. The information below will assist you in making an educated decision on which separator is the best solution for your application.

1: The Four Types of Oil in Water

Oil contamination of water can present in 4 different forms. Each form requires a different treatment strategy.

You must know what types of oil pollution you have so that you can select the right treatment option for your application.

Not sure what mix of the 4 types of oil contamination you have? Let us help!

Feel free to give us a call or send an email. We can use our experience and extensive oily water database to get you started!

Take advantage of our extensive in-house oily water test facilities and laboratory. We are are able to analyse and characterise your oily water problem and give you a full report. In many cases we can even do this for free!

2: Critical Oily Water Design Factors

There is no ‘one size fits all’ oil separator. Choosing an oil separator without knowing the type of oily water it is expected to treat is a recipe for disaster!

In the previous section we explained the different types of oil pollution you can experience in water. Combine this knowledge with a few other key parameters listed below to accurately define the oily water that needs to be treated – this is typically called the influent.

Flow Rate

Why it is important

- This will determine the size of separator you need.

- If you have a low flow rate then you can install a more economical system. If you have a high flow rate then you will need a system which can keep up to avoid compliance issues and costly remediation

Oil Load

Why it is important

- If there is a lot of oil coming into the system and your oil tank is too small then you will end up needing to empty it multiple times a day to prevent the oil tank from overflowing.

Discharge Location

Why it is important

- Where you intend to discharge your oily water will determine the treated water quality required.

- Usually your local water authority will provide guidelines and limits based on where you want to discharge your water.

Nature of the Oil Water/Treatability

Why it is important

Understanding the nature of the oily water will determine how powerful your separator needs to be and what type of oil separator you might be able to use for your application.

- Separator Power:

- Oil droplet size is the most important factor to determine the treatability of your water. Once you know the average oil droplet size in your water, you can then determine which separator technologies can treat your water. The power you need in the separator must match the oily water you have

- Type of separator:

- Not all separators are designed or suitable for all oily water types. There is nothing more disappointing than spending good money – only to find out that you have used the wrong type of separator!

- For example – Coalescing type separators (CPS, VGS, CPI) all work on “coalescence”. If you have detergents or other surfactants in the water they will prevent coalescence and therefore those types of separator will not be a good choice for your application.

3: Oil Droplet Size

Oil Droplet Size

Why it is important

- Oil droplet size determines how powerful your oily water separator needs to be

- The smaller the average oil droplet size in your water, the more powerful you separator needs to be.

- All types of oily water separator have different limitations on the droplet size that they can treat.

How do you measure it?

- The most accurate way to work out the average oil droplet size is to measure it directly. This needs to be performed on site in real time. The droplet size in a static sample changes overtime so it won’t reflect actual site conditions.

- At Ultraspin we have a Video Particle Analyser which we use to determine droplet size. If you would like to know your droplet size, we can send one of our skilled technicians on-site with our particle sizer and measure it for you.

- If you don’t have access to a particle sizer then there are a few methods to estimate droplet size detailed below

Estimating Oil Droplet Size: Visually Compare Water Samples

You can also get a rough idea of your oil droplet size with a visual inspection of your sample. In general, if you can see the droplets with the naked eye, they are large and generally greater than 150 micron. If the water looks hazy, white or milky, the droplets are very small (less than 25 microns, often less than 10 micron). We have a data base of sample photos from thousands of applications with matching droplet sizes to give you a visual guide. Look for a sample that has similar characteristics to yours. If you need help, check out our sampling page and email us a photo of your sample and our oily water engineers will help you.

Estimating Oil Droplet Size: What is Typical for the Application?

Most of the time a good place to start when trying to determine your oil droplet size is to look at similar applications. Over time we have determined what a typical mean oil droplet size is for common sources of oily water, as shown below. The actual mean oil droplet size will depend on site practices but this chart is a good way to quickly narrow your options.

4: What Separator Can Treat my Oily Water

Now that you understand the 4 types of oil contamination, the particular mix of types you have and the importance of oil droplet size:

You can begin to short list the types of oil separator that might work for you

A good place to start is with oil droplet size. You can narrow down your choice of oil separator technologies that suit your application based on what droplet size each separator technology is designed to treat. Keep in mind that this table helps with technology selection related to removing oil droplets only. Some separation technologies are also affected by chemicals, surfactants and suspended solids, and ruled in or out based on those considerations (see below).

5: Performance Guarantees

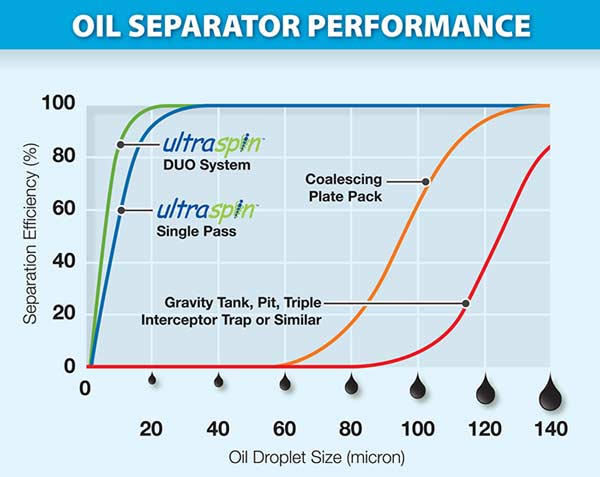

Oil Water Separator Performance Curves

Now that you understand the importance of oil droplet size you will now be able to understand Oil Separator Performance Curves. Many factors affect the performance of an oily water separator system. For most customers a primary consideration is oily water separation ability because this defines final discharge water quality or oil recovery rates.

Oil Separation efficiency can be expressed as follows:

Oil Separator Efficiency (%) = 100 x ( Cin – Cout / Cin)

- Cin = feed inlet concentration (mg/l)

- Cout = discharge outlet concentration (mg/l)

More powerful separators have a number of advantages including obtaining better quality discharge water, meeting or exceeding Local and National Trade Waste discharge standards, meeting or exceeding future discharge standards, dealing with accidental oil spills and tolerating a higher strength or a higher concentration of detergents and cleaners.

Oil Water separation efficiency can be objectively assessed by examining the separator oil droplet size vs. separation efficiency curves. For higher quality separators these curves should be readily available from manufacturers. Manufacturers should also be able to confirm performance to these curves through independent testing. The purpose of oily water separators is to obtain clean water, however, claims of a separator being able to achieve less than 10 mg/l discharge are meaningless and deceptive without reference to oil droplet size performance curves.

Caution: There are oily water vendors who can’t measure the oil droplet size as they don’t own the specialised equipment required. You should not trust vendors who cannot measure oil droplet size. They can only guess how their equipment will work in your application.

You would not trust a pressure vessel manufacturer who is unable to measure pressure, or an oven manufacturer unable to measure temperature. It sounds ridiculous – but it happens!

Always ask your supplier for an objective oil droplet based performance curve like the one shown here. Make sure it is one they have generated by measuring oil droplet size on their equipment, and not copied from another vendor like Ultraspin. Compare the curve to the oil droplet size you have or need. If a supplier cannot or will not send you their own performance curve – be very wary!

6: Other Oily Water Fluid properties

Mean oil droplet size is the single most important factor for defining the dirty oil water, but there are several other factors to also consider.

Temperature

The viscosity of the water falls as the water temperature rises. This allows oil droplets to move more easily through the water phase, thereby producing better oil separation with many oil water separators (but not all). Therefore, increased temperature improves separation efficiency for most oily water separators. The Ultraspin separator can be supplied to operate within the temperature range 0 to 120°C (32 to 248°F), at higher temperatures special materials may be required.

Oil Separators that work better at higher temperatures include:

- Ultraspin Separators (0 to 120°C)

- Coalescing plate packs (5 to 80°C)

- Gravity tanks and vessels (5 to 90°C)

- Centrifuges (5 to 90°C)

Oil Separators that may not separate as effectively at higher temperatures include:

- Air flotation devices (DAF, CAL, IGF) (5 to 30°C)

- Media filters (5 to 45°C)

- Membranes (5 to 65°C)

- These types of separator may require water coolers to work effectively.

Density Difference

For many oil separators the oil removal efficiency is dependent on the difference in density between the contaminant and the water. The separation efficiency increases as the difference in density increases. The density difference can increase if you have lighter oils or your water is salty, or both. Typical densities for Oil are 950 to 750 kg/m3 (0.034 to 0.027 lb/in3) and Water : 1050 to 995 kg/m3, (0.038 to 0.036 lb/in3).

For the below oil separators, performance improves as the density difference increases. Generally, the density difference must be more than 25 kg/m3

- Ultraspin Separators

- Coalescing plate packs

- Gravity tanks / SPEL / Triple and double interceptors

The types of oil separators below are not greatly effected by small density differences (say less than 25 kg/m3):

- Media filters

- Membranes

- Air flotation (DAF, IAF, CAF)

Inlet Concentration

Some types of oil separator are NOT well suited to high oil feed concentrations which can overload or block the systems. For these types of system, careful pre-treatment is required to remove oil.

- Coalescing plate packs (max 1% oil or 10,000 mg/l).

- With high oil concentration, the plates become coated in oil and sludge. This requires the plates to be removed and cleaned to restore oil removal efficiency.

- Air flotation systems (DAF, IAF, CAF) (max 1% oil or 10,000 mg/l)

- Media filters (typical max 100 mg/l oil )

- Membranes (typical max 300 mg/l)

Other system types can accommodate 100% oil concentration for a period of time:

- Ultraspin systems

- Centrifuges

- Gravity tanks / SPEL / Triple and double interceptors