You deserve a better oil skimmer that…

More effectively removes all the oil, fat or hydrocarbon

Does not need continual adjustment or maintenance to keep it working

If that’s what you need – we have the answer!

Oil skimmer floating in the sump of an Oil Company fuel bay.

An oil skimmer on a mine site equipped with a trash screen, hose and hose float.

An Oil skimmer installed at a Dairy Factory.

S2 oil skimmer removing hydrocarbons on a South African mine site. We export our skimmers all over the world.

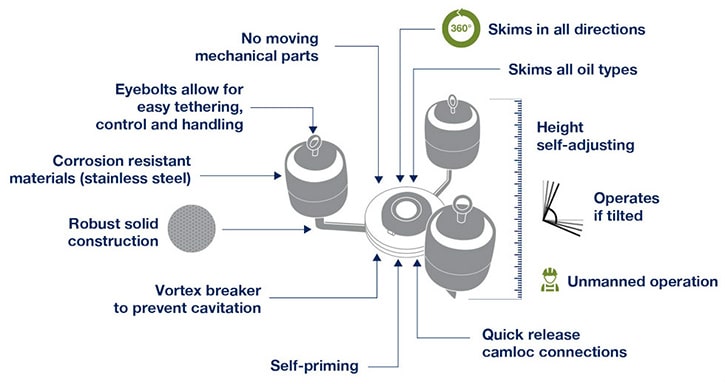

Clever design features of the Ultraspin Floating Oil Skimmer

The Ultraspin Oil Skimmer:

- Oil removal rate up to 25m3/hr

- A floating weir that automatically adjusts to changing water flow rates

- The weir automatically stays level even if the skimmer tilts

- No moving parts which means little to no maintenance

- Skims in all directions for complete oil removal

- Set and forget, no operator input required

Ultraspin Model: S1

Flow rate up to 7m3/hr

Ultraspin Model: S2

Flow rate up to 25m3/hr

How does the Ultraspin Oil Skimmer Compare?

|  |  |  |  |  |

|

|---|---|---|---|---|---|---|

| $ EXPENDITURE | ||||||

| Low capital & installation $ | ||||||

| Low operating & maintenance $ | ||||||

| FEATURES | ||||||

| Treats the water | Oil skimmers do not treat the water | |||||

| Easy to deploy | ||||||

| Simple service and maintenance | ||||||

| Can feed an oily water separator | ||||||

| Skims in all directions | ||||||

| No operators required / self-adjusting | ||||||

| No flame proofing required | ||||||

| No electrical safety concerns | ||||||

| No safety guards/pulleys/motors required | ||||||

| SKIMMING EFFECTIVENESS | ||||||

| Equally effective with all oil types | ||||||

| Not affected by chemicals or detergents | ||||||

| High oil removal flows rates | ||||||

Places our Oil Skimmers are used successfully:

- Mining

- Refinery and Petrochemical

- Oil spill cleanup

- Steel mills

- Machining / CNC / Parts manufacturing

- Transformer bunds

- Abattoir, Slaughterhouse, Meat processing, Meat packing

- Machine sumps

- Food Processing

- Electrical power generation / hydro

- Ground water remediation

How it Works

Get a Personalised Consultation

Accessories and Options

Flat Packs

Suction Hoses

Hose Floats

Low Shear Pumps – Electric

Low Shear Pumps – Pneumatic

Trash Screens

Skimmer Lifting Slings

Lifting Winches

Oil Storage and Decant Tanks