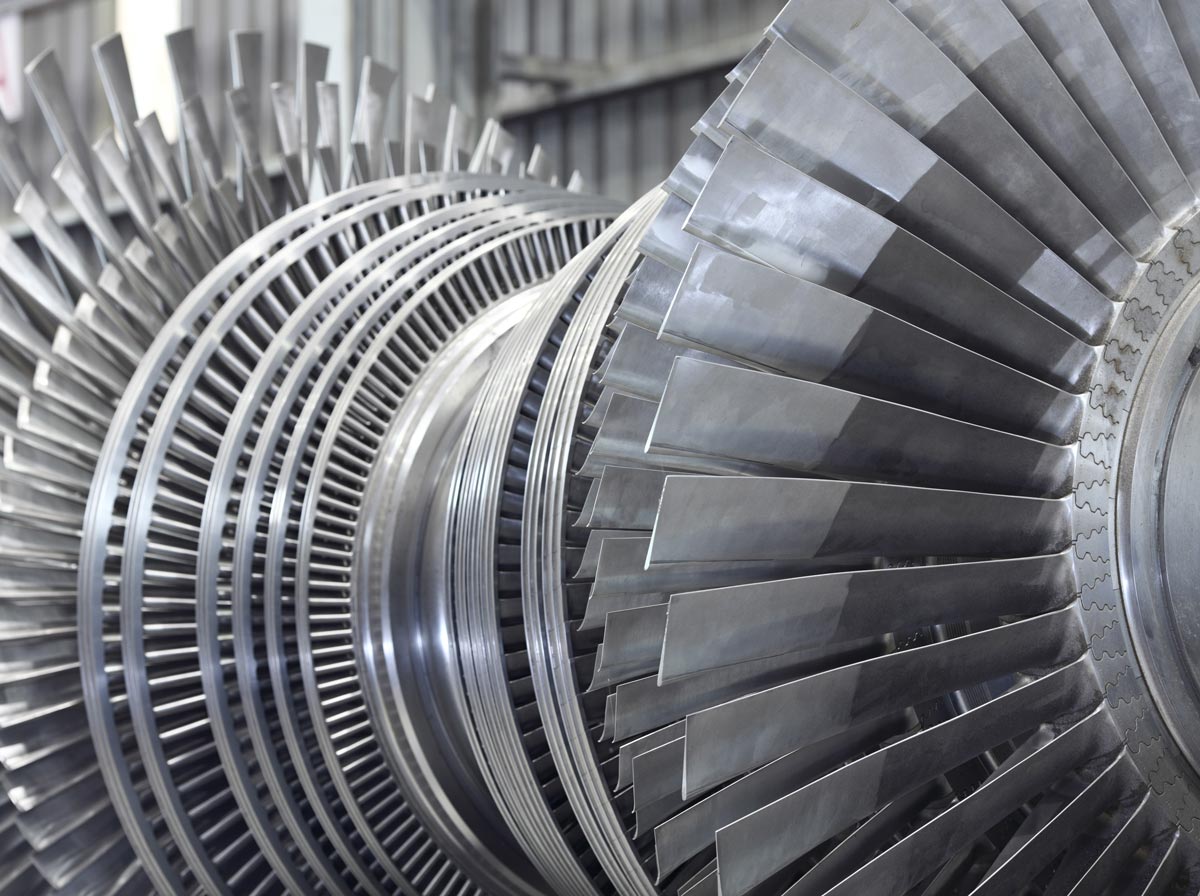

Australia’s power comes in many forms – hydro, coal, solar, wind and diesel generation. All of which have oils to keep our energy turning over smoothly.

My power generation equipment creates oily water – what do I do with it?

Bunded oily water is easily treated with an Ultraspin Oily Water Separator System

A typical power generation site or sub station will have a bank of generators and transformers that needs maintenance in situ, creating sources of oily wastewater.

Whatever the source of power, there will be bunded oily water.

At Ultraspin, we have the ability to help you design a system of oily water separation using our unique separators for environmental compliance that will:

- Be a system that copes with variable input flow

- Require little or no maintenance

- Require no operator supervision

- Be more cost effective compared to the life cycle of plate packs

- Comply with local discharge standards

- Be easily installed in new systems or retrofitted

With the Ultraspin Oil Separator, your wastewater will be cleaned quickly and efficiently.

How does the Ultraspin Oil Separator remove the oils?

Oily water is pumped into a precisely engineered tapered pipe, creating a vortex generating 1,000 times the force of gravity. Under such force the heavier water is pushed to the outer edge of the vortex and discharged from the the smaller end while the lighter oil moves to the centre of the vortex and dispelled from the broader end.

It has no moving parts, rarely needs cleaning, works much faster than gravity, and is powerful enough to treat even 15 micron oil droplets!

Find out more about Ultraspin separators

There is one thing you must know before choosing an oily water separator: what size oil droplets do you have?

It is a fundamental question, as it will determine what micron rating you require and therefore which separator type will be suitable for your application.

Need more information on oil droplet size?

Case study

Contract Power, Power generation

Christmas Creek and Cloudbreak, WA

The Christmas Creek and Cloudbreak mine sites in the Pilbara are owned and operated by Fortescue Metals Group, processing around 60 million tonnes of iron ore on site per year.

The remote locations require substantial power for processing and FMG commissioned Contract Power Group to install the necessary diesel generators. The Christmas Creek site generates 58MW while Cloudbreak produces 30MW.

To provide high standards of OH&S, the generator buildings must be kept clean requiring regular wash downs to remove oils and grime that may have accumulated from maintenance activities or minor oil spills. Consequently, Contract Power installed a channel behind the generators to collect the oily water to facilitate treatment.

In both sites, Ultraspin worked with Contract Power to supply an oily water separator designed to cope with 3.5m3/hr and oil loads that can vary substantially from very little to near 100% if a spill occurs. The output discharge needs to be less than 15mg/L TPH in order to meet the mine site environmental license.

The two sites are a feather in the cap for Contract Power, but the water treatment system is a credit to the Ultraspin solution.