Why an Ultraspin Oil Separator?

- Powerful

- Lowest Ownership Cost

- Simple and Reliable

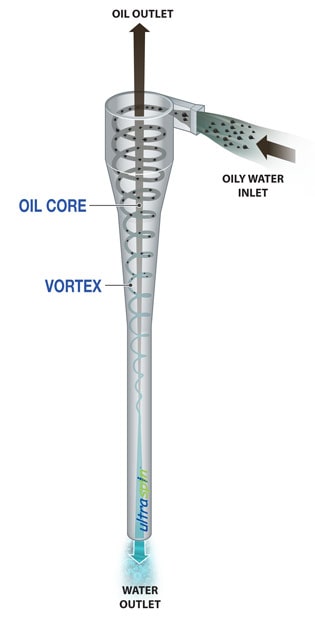

How does the Ultraspin Oil Separator work?

Like many oil water separators, the Ultraspin system separates the oil/fat and the water based on the density difference – the oil/fat droplets being lighter than the water. To do this the oily wastewater is pumped tangentially into the separator which forms a powerful vortex and huge centrifugal forces. The force created, squeezes the lighter oil/fat droplets into the center of the vortex and two streams are generated: treated water ready for discharge or reuse, and the separated oil for storage and disposal.

- The centrifugal separation force generated is over 1000 times the force of gravity!

- Separates emulsified oil droplets as small as 10 microns!

The Ultraspin separator is one of the simplest and most powerful oil water separators available. And all with no consumables and no chemicals!

See it for yourself!

Oil Water Separator Product Range

We have a range of oil water separator options that cater for most oily water applications. Follow the links below for further information.

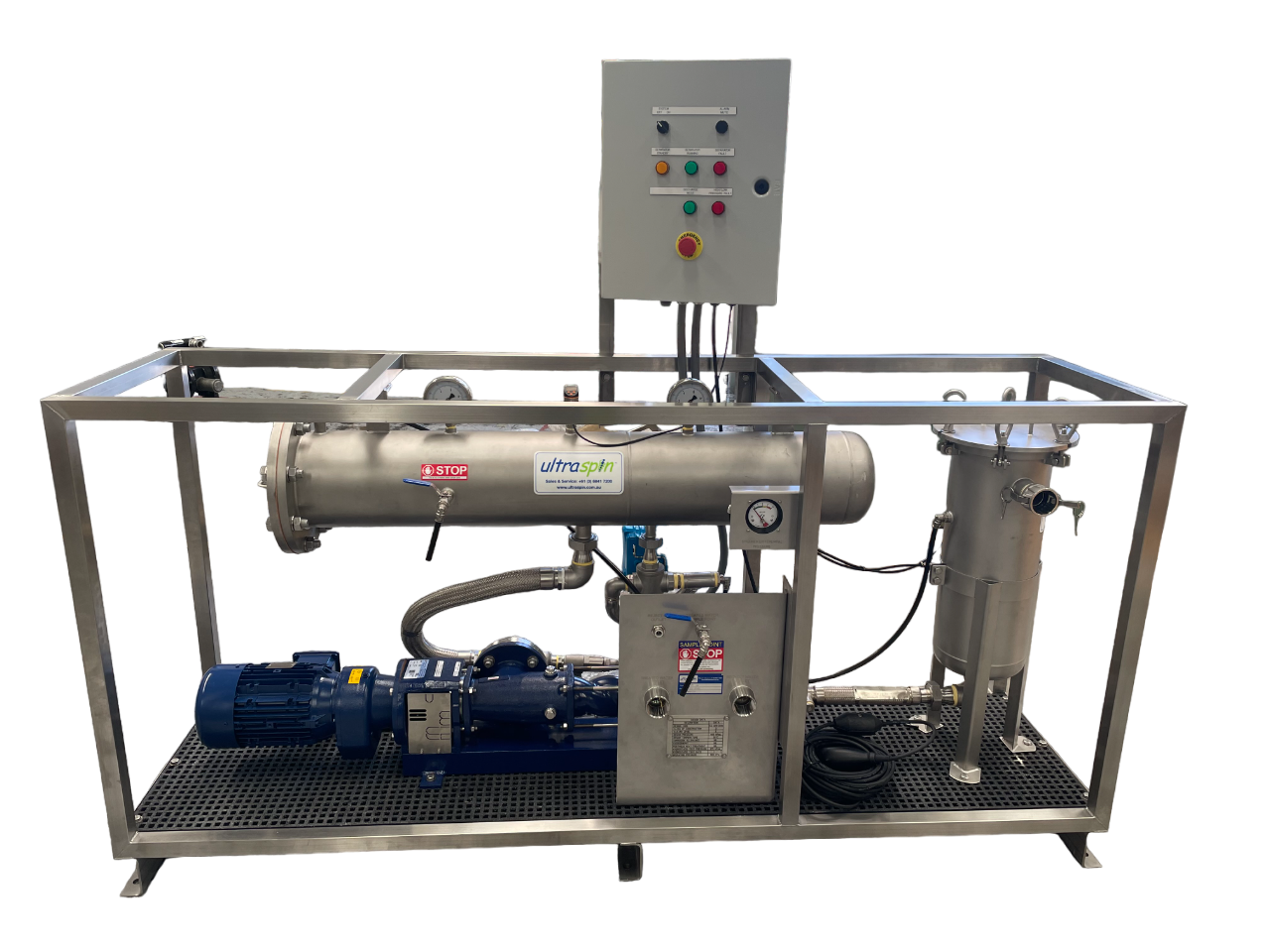

Pneumatic EDGE System

- Up to 7 m3/hr

- 15 to over 150 micron oil droplet size rating options

- Compressed air powered

- Pneumatic controls

- Flameproof

Electric EDGE System

- Up to 7 m3/hr

- 15 to over 150 micron oil droplet size rating options

- Electric powered including controls

- Pump dry run protect standard on oily water separator

- Backflush option available

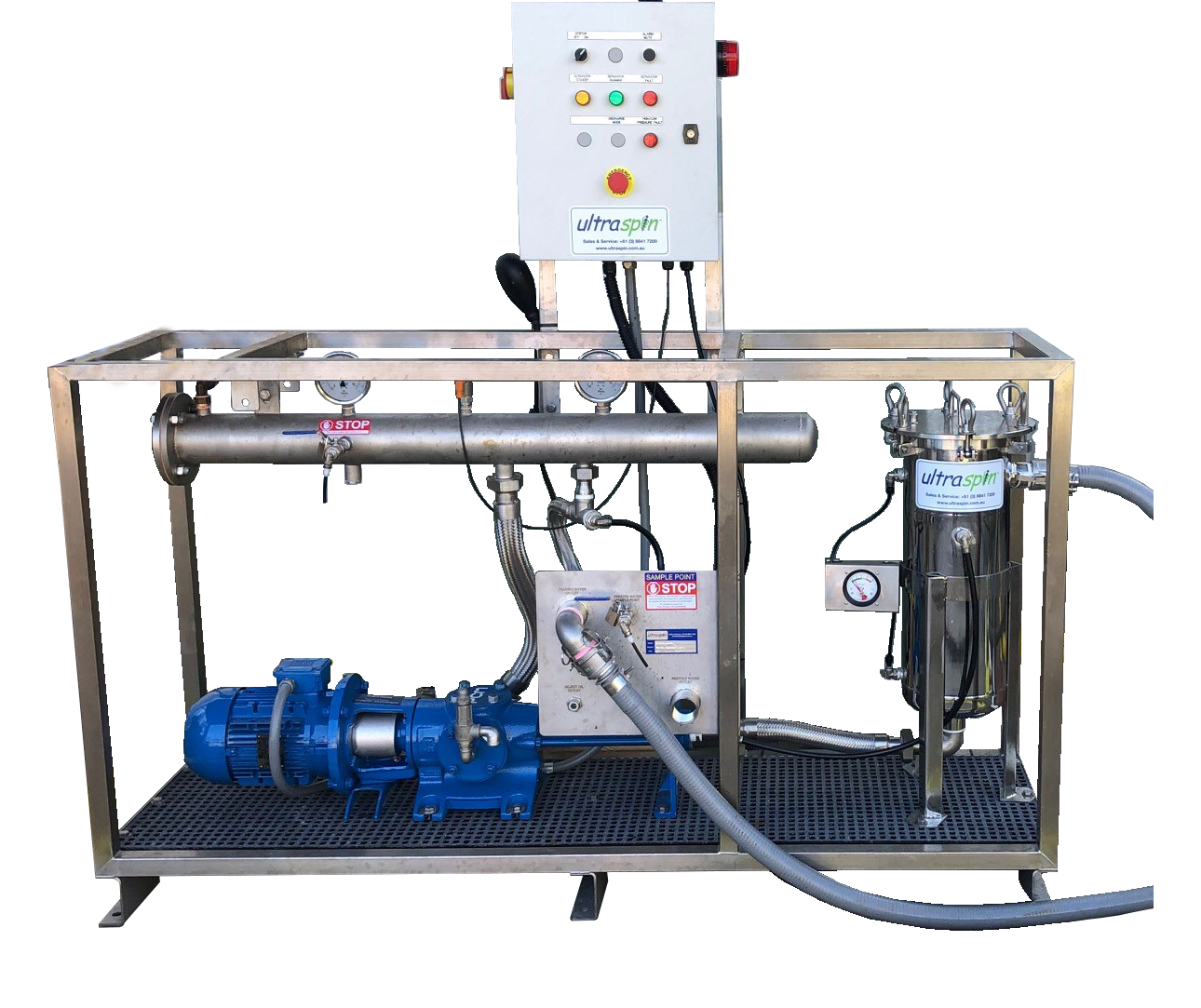

Electric Heavy Duty (HD) System

- 15 to over 100 m3/hr feed flow

- Heavy duty construction

- Electric powered including controls

- Can be built to customer specifications

- 15 to 150 micron oil droplet size rating options

- Pump dry run protect standard on oily water separator

- Backflush option available

SuperCubi System

- Two options:

- Up to 3 m3/hr feed flow

- Up to 10 m3/hr feed flow

- Heavy duty construction

- Electric or Pneumatic options available

- Can be built to customer specifications

- 15 to 150 micron oil droplet size rating options

- Self-contained

Pneumatic Systems

Small Flow Electric Systems

High Flow Electric Systems

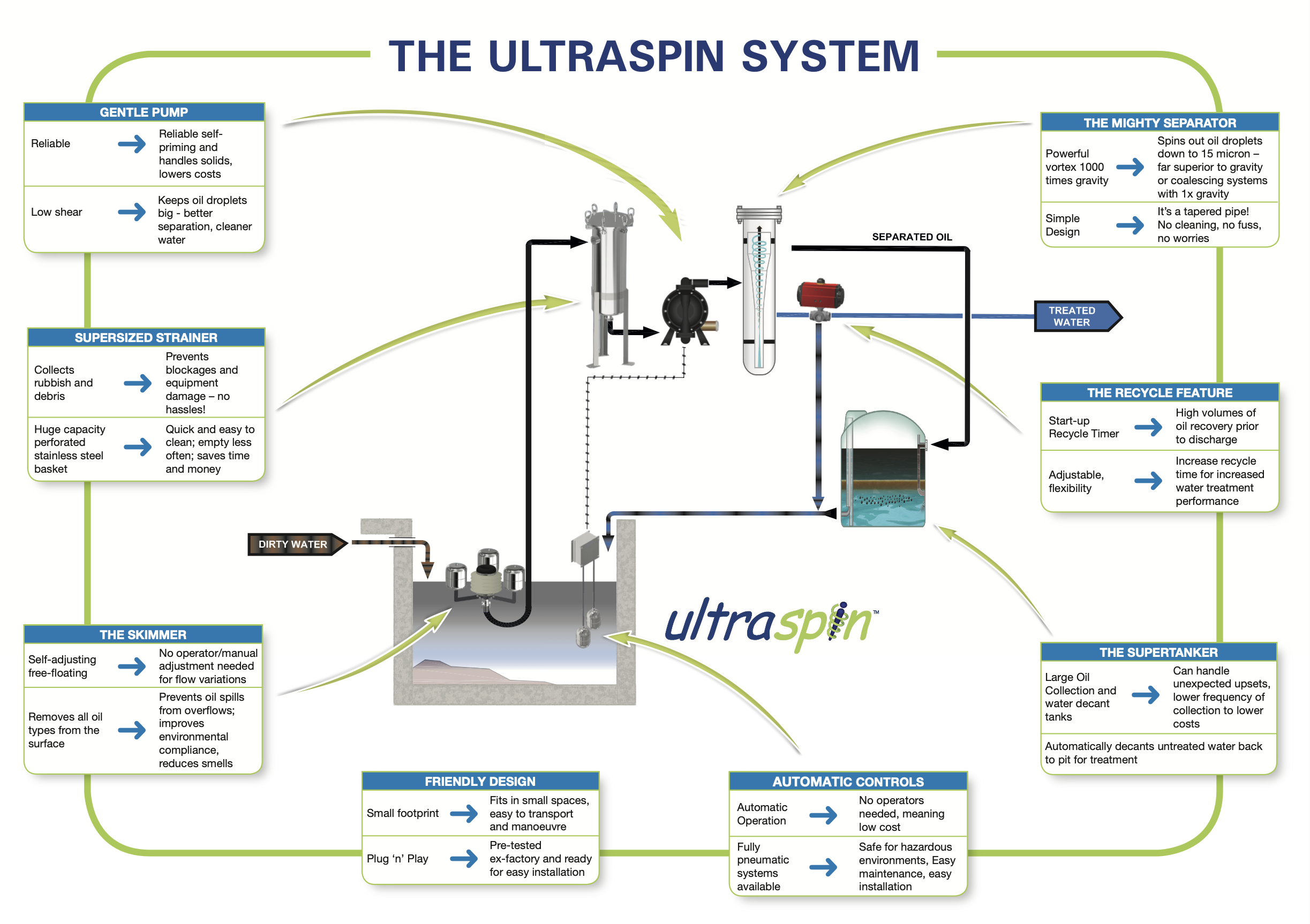

You need a complete solution:

– Treating all oil types

– All the critical components

- Oil Skimmers

- Large Debris Strainers

- Low Shear Pumps

- VBO Tanks

- Clever Controls

“Works like a champion”

A powerful oil separator – with a complete package

With an Ultraspin oil water separator you get a high performance system which is reliable, low risk and requires very little maintenance. We are able to achieve this at Ultraspin by providing you with a complete system that includes large strainers, oil skimmers, large oil storage decant tanks and control equipment as standard. There are no surprises so you know exactly what your costs will be.

Oil Skimmers

The Ultraspin oil skimmer is an important part of many of our oil separators. Why do we like them so much?

- Greatly improve the overall water discharge quality

- Minimise the risk of oil spills if the pit floods (no oil on top to overflow)

- Reduces flammable risk – no oil on top to catch fire

- Less pit pump-outs when no oil gets built up

- Eliminates nasty odours

Our skimmers are floating, self-adjusting and weir style, this means with fluctuations in water flow or skimmer positioning, it will adjust itself automatically and continue to operate as normal. Find out more by visiting our Skimmer page

Strainers – bigger is better

Our systems include very large, high capacity, easy-to-clean strainers. 30 years of experience tells us a strainer is essential for protecting the pump and other equipment from wear and damage. All kinds of debris collects in an oily water pits; leaves and twigs, cigarette butts, feathers, food packets, cable ties, even beetles and other insects!

A great advantage of our systems is our large strainer size and our customers really enjoy this detail. Most competitor oil water separators do not come with a strainer at all, meaning their equipment gets damaged quickly which forces downtime and requires costly spare parts.

Ultraspin strainers are designed with the operator in mind:

- Large capacity – reduce the frequency of emptying and monitoring

- Quick and easy to clean

- No heavy lifting or bending over, can be cleaned by one person without any special tools

- Robust perforated stainless steel (not mesh) so debris doesn’t get stuck or damage the strainer

Oil Storage Tanks – Size Matters

- An oil water separator’s job is to remove oil – and lots of it. Many of our competitors don’t supply an oil tank, and when they do, its tiny! The Ultraspin Separator has powerful separation capabilities which means a larger tank is necessary for your convenience and peace of mind. An added automatic water drain also ensures that the water in the recovered oil is decanted automatically. These factors mean less time checking if your tank is over-flowing or needs emptying – saving you money in waste disposal fees.

- Available in a variety of materials to suit your needs and budget, the Ultraspin oil storage and decant tank can be made from common materials including Stainless Steel and Polyethylene – if required we can also make our tanks double walled.

- Ultraspin tanks can be supplied to comply with your specific regulations. Common examples include storage of separated materials of non-hazardous liquids, hazardous goods class 9, combustible liquids and many others. Let us know what your requirements are and we can find a solution that fits!

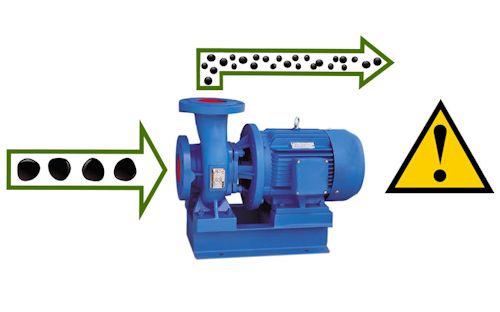

Low Shear Pumps

Being a hugely important part of an oil water separator, here at Ultraspin we are very fussy about pump selection. An unsuitable pump can be detrimental to the performance of an oil water separator. Using our oil droplet particle sizer, we quickly identify pumps that ‘shear’ or break up oil droplets which emulsifies the oily water and subsequently increases the difficulty of oil separation. Most vendors don’t have equipment to measure oil droplet particle size and therefore often select pumps based only on cost. What results is poor oil water separator performance and costly consequences for their customers.

At Ultraspin we design, select and performance test (with one of our oil droplet size tools) all of our pumps to make sure that they are gentle on the oily water and give the best possible oil water discharge quality. Correct pump selection is an important reason our systems work so well. We offer pneumatic and electric pumps of varying materials to suit your application.

Clever Controls

We provide pneumatic and electric control systems that can be manual or fully automatic. Should you require additional control features we can also offer:

Start up Recycle: Allows the removal of thick oil layers before treating and discharging water. Multiple treatment of water to increase overall oil separation efficiency when oil droplets are very small or higher water quality discharge is required.

Choosing an Oil Separator

Not sure where to start?

If you’re not an oily water expert don’t worry. In our Learning Centre we have put together a wealth of information that will turn you into an expert in no time!

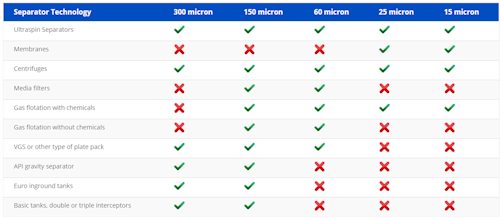

The Importance of Oil Droplet Micron Rating

The single most important thing when selecting an oil water separator is knowing its oil droplet size micron rating. Large oil droplets are easy to separate and most separators will do that, but if your oily water mixture contains smaller oil droplets you will need a more powerful separator with a lower micron rating.

Want to compare different Oily Water Separation technologies?

Are you confused by the capabilities of Coalescing Plate Separators, VGS, European ‘5 mg/l’ tanks, DAF’s, Media filters or centrifuges? We can provide some information to help you decide.